We are committed to be

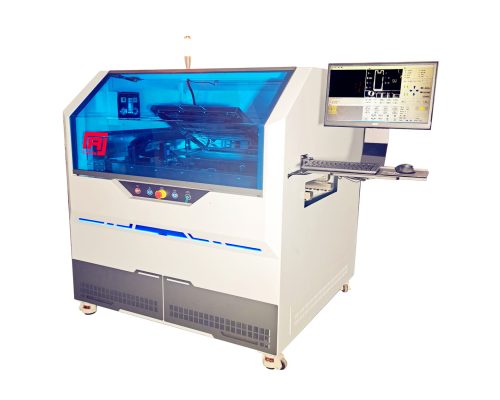

The Best Selective Soldering Machine Manufacturer

We are the leading manufacturer of selective soldering machines, renowned for our unwavering commitment to quality, innovation, and performance. We specialize in creating state-of-the-art selective wave soldering machines that cater to a diverse range of industrial needs, ensuring precision and efficiency.

About Us

Reliable Selective Soldering Machine Manufacturer

Selective Soldering Machines Technology Co., Ltd. is a professional selective soldering machine manufacturing factory with over 15 years of experience. The enterprise boasts a 6,000-square-meter standard workshop with a professional independent R&D team. It has focused on selective wave soldering machines research and development manufacturing for many years and has established an industry-university-research cooperation mechanism with several universities. The company currently holds 12 national technology patents. Our eternal pursuit is studying practical technology and continuously innovating to provide customers with better products and services!

All Selective Soldering Machine Products

Selective Soldering Machine Benefits

Selective soldering machines bring a host of advantages that bolster productivity, enhance quality, and offer unmatched versatility in soldering operations, especially for intricate electronics manufacturing:

- Improved Accuracy and Quality: Featuring advanced computerized programming, selective soldering machines precisely apply solder to designated areas on a circuit board, ensuring each connection is perfectly executed. This precision significantly diminishes the likelihood of human error and defects, yielding high-caliber products and driving down the costs of rework and repairs.

- Increased Efficiency and Productivity: With the capability to solder more quickly and accurately than manual soldering methods, selective soldering streamlines production times and minimizes labor expenses. Its adeptness at managing high volumes proves invaluable for substantial production endeavors.

- Resource Efficiency: Selective soldering stands out by consuming less flux and solder compared to traditional hand soldering, translating into noticeable cost reductions over time.

- Compatibility with Double-Sided PCBs: Double-sided PCBs, prevalent in today’s complex electronic designs, are easily accommodated by selective soldering machines. This compatibility is a significant advantage, enabling manufacturers to tackle more sophisticated and dense circuit layouts.

Selective Soldering Machine Applications

Selective soldering machines are utilized in various applications where precision and protection of sensitive components are crucial. They are particularly beneficial in scenarios where printed circuit boards (PCBs) have components that could be damaged by the heat of a traditional wave soldering process. Below are some of the key applications of selective soldering machines:

Complex PCB Assemblies

Selective soldering excels in the soldering of complex PCBs post-SMT (Surface Mount Technology) oven reflow, especially for boards with heat-sensitive components.

Through-Hole Component Soldering

These systems are highly efficient at attaching through-hole parts on PCBs, offering a speed and repeatability that manual soldering cannot match.

Automotive Electronics

In the production of automotive electronics and switching power supplies, selective soldering is crucial, as it ensures dependability in extreme conditions.

High-Density PCBs

The precision required for flux application and soldering on multilayered and densely populated PCBs is well within the capabilities of these machines.

Non-Electronic Applications

Their use extends beyond electronic soldering, encompassing tasks like securing lead-frames to ceramic bases and affixing coil leads.

Why Choose Us as Selective Soldering Machine Supplier

Opting for our selective soldering machines as your provider brings a multitude of benefits:

Improved Accuracy and Quality

Our selective soldering machines targeting only designated zones on the PCB for soldering, the likelihood of errors is notably minimized, resulting in superior end products and minimizing the need for costly do-overs.

Efficiency and Productivity

Our equipment streamlines your operations by accelerating the soldering process, while ensuring higher accuracy than old-school soldering techniques. This contributes to swifter completion times and shrinks labor expenses.

Flexibility

The machines we offer bring unparalleled flexibility to the soldering process. They can swiftly adapt to evolving manufacturing needs and merge smoothly with robotic production systems.

Consistency

In contrast to the variable nature of manual soldering, our selective soldering system delivers consistent results time after time, ensuring a dependable solder joint with every application.

Safe Processing of Materials

Our systems facilitate safe handling of non-lead materials, which is key as industry standards move away from lead-based soldering, all while protecting the entire board from excessive heat.

Advanced Features

Our machines boast advanced capabilities, including precise controls over wave height, duration on solder, and temperature settings. This level of control is essential for executing the soldering of complex, densely packed PCBs.

Cost-Effective

Though there is an upfront cost, the efficiency and time-saving attributes of selective soldering typically ensure a swift return on investment. Over the long haul, this translates into meaningful cost reductions and boosted profitability.

Support and Maintenance

We commit to providing thorough support services and rapid troubleshooting. Our machines are also constructed with ease of maintenance in mind, thus guaranteeing ongoing dependability and top-notch functionality.

Selective Soldering Machines Manufacturer Certifications

At Selective Soldering Machines, we pride ourselves on the quality and safety of our products. To demonstrate our commitment to meeting the highest international standards, we’re proud to hold the following certifications and accreditations:

Blogs About Selective Soldering Machine Manufacturing

The selective soldering machine applies solder only where needed using a single head, leaving the rest of the board untouched. In contrast, wave soldering applies a high-temperature molten solder to the entire board, resulting in faster but less precise soldering.

How to select soldering iron tips?

This guide will explore the essential considerations when selecting soldering iron tips, the various types available, and key factors to keep in mind to streamline your soldering experience.

The Lifespan of Soldering Flux: How to Ensure Optimal Performance

This article delves into the shelf life of soldering flux, its degradation signs, and the impact of using expired flux on soldering quality. We will also cover the proper ways to store soldering flux to maximize lifespan and performance, ensuring you don’t encounter unexpected setbacks in your soldering projects.

How much nitrogen does selective soldering use?

This discussion provides an in-depth analysis of the role and benefits of nitrogen in selective soldering, including the amount of nitrogen used and its impact on the quality and efficiency of the process. In addition, we will examine the various factors that determine the appropriate nitrogen concentration for selective soldering and suggest suitable alternatives to nitrogen.

Frequently Asked Questions (FAQs)

Selective Soldering Machine Price/Cost

The price of a selective soldering machine can vary widely depending on the features, brand, and capabilities. Contacting us directly or requesting a quote based on your specific requirements is recommended for the most accurate pricing.

Selective Soldering Machine China

As China’s premier manufacturer of selective soldering machines, we take pride in being at the forefront of the industry, providing state-of-the-art solutions tailored to sophisticated electronic assembly processes. Our reputation for excellence stems from our relentless pursuit of innovation, quality, and customer service. With a rich heritage of engineering expertise and a keen understanding of the dynamic market, we deliver machinery that stands out for its reliability, precision, and advanced capabilities.

What is the warranty of your selective soldering machine?

Our company’s warranty for our selective soldering machines typically covers one year from the date of purchase. This warranty includes parts and labor for any manufacturing defects or malfunctions that may occur under normal operating conditions. During the warranty period, if any issues arise, we will provide repair services or replacement parts at no additional cost to ensure your machine remains operational and efficient.