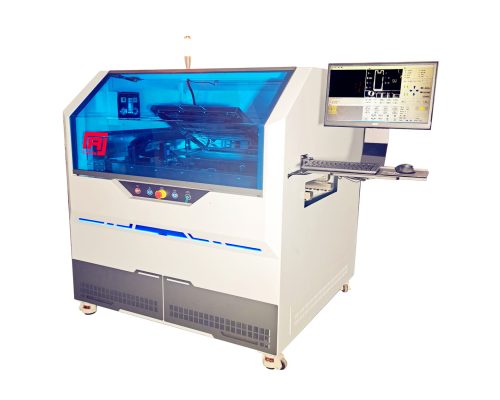

Combined Selection Soldering Machine for Sale

Combined Selection Soldering Machine

Product description

Basic requirements: selective wave soldering site

| The serial number | According to | parameter |

| 1 | Machine operating voltage | Single phase 220v,50HZ |

| 2 | Machine operating temperature | 10 — 40℃ |

| 3 | Machine operating humidity | 20%-80% |

| 4 | Machine external open requirements | 60A |

| 5 | Machine air source requirements | 3-5 bar |

| 6 | Machine exhaust flow requirements | 0.2 cbm/hour |

| 7 | Machine dimensions | L4000 x W1400 x H1500 mm |

| 8 | Machine weight | 1500KG |

| 9 | Make room for the front and rear of the machine | >=1.5m |

| 10 | nitrogen | 02 < 20 PPM |

Technical parameters

| PCBplate | |

| The minimumPCBsize | ≥L60mm ≥W60mm |

| The biggestPCBsize | ≤L400mm ≤W400mm |

| PCB The thickness of the | 0.5~6.5mm |

| PCB The weight of the | Max.9Kg |

| PCB The upper part of the space | ≤130mm |

| PCB The lower space | ≤50mm |

| PCB Process side | >3mm |

| PCB Transportation Angle | 0° |

| Tin furnace and welded parts | |

| Tin furnace capacity | 8Kg |

| Tin furnace materials | High strength stainless steel or titanium alloy |

| Tin furnace heating mode | PID |

| Tin stove temperature | At room temperature~350℃ |

| The temperature control accuracy | ±3℃` |

| Tin wave height | ≥5mm |

| Crest height detection | There are |

| Minimum nozzle size | Φ3mm |

| N2The supply of | 0.5Mpa 20L/min |

| N2The purity | O2 < 20 PPM |

| Dissolve hot time | ≤50MIN |

| Number of nozzles for tin furnace | 1PCS |

| Transportation part | |

| Wheeled transport | There are |

| Transport height | 900+/-20mm |

| Transport direction | Left to right |

| Transportation motor | Stepper servo motor |

| PCB Transportation speed | 0.2~10 m/min |

| PCBPositioning way | Mechanical positioning |

| Transport guide | Fixed before,After moving |

| Adjustable wide way | Step servo automatic widening |

| Spray part | |

| Spray way | Linear jet |

| Flux type | Request to support wash – free type/Water base type |

| Flux capacity | 1-1.5L |

| Flux container | Pressure tank |

| Spray working pressure | 0.5~1bar(0.05Mpa~0.1MPa) |

| Preheating section | |

| Effective preheating area | L400mm×W400mm The above |

| Preheating temperature | At room temperature~100℃ |

| The temperature control accuracy | ±3℃ |

| The temperature control mode | PID Closed-loop control |

| Heating mode | Infrared heating |

| Software part | |

| The operating system | Windows7 |

| Software language | Simplified Chinese and traditional Chinese, English |

| programmatically | Offline, online |

| Data import | Support Gerber image conversion, image scan import |

| Integrated part | |

| The power supply | Optional 1P220V50HZ OR 1P110V60HZ (optional 110V and 220V switchable power supply) |

| Normal machine power/total power | 2KW/10KW |

| Mode of motion of motion module | PCB board does not move, XYZ platform movement |

| Online way | SMEMA |

| Visual identification | There are |

| Visual deviation adjustment | There are |

| Maintenance reminder | There are |

| Welding phase monitoring | There are |

| Solder level alert alert | There are |

| Spray head cleaning | There are |

| Single/double flux tank | double |

| N2 pressure warning system | There are |

Equipment features and function description

The Tairjia product has a wide application range and is designed to cooperate conveniently with the factory’s automatic production line. It can weld multiple sets of expansions and fuse various mixed PCB boards directly through the fixture.

Regarding the advantages and disadvantages of single-head selection welding, it is essential to note that while the single head has lower working efficiency, it can still be used to improve the efficiency of more than one joint.

Double-head welding has both advantages and disadvantages. While it offers high work efficiency, adjusting welding process parameters and position is more complex than single-head welding due to the fixed tin furnace on the same platform. Additionally, each product must be made with a special jig. If one of the welding heads experiences an abnormality or failure, the single head can still work, but the entire machine cannot function properly, requiring maintenance. It is important to note that the content of the improved text must be as close as possible to the source text, and no new aspects should be added. The maintenance time is also lengthy, and the two wave peaks exhibit poor working stability simultaneously.

This soldering system is suitable for any occasion. Its high performance is attributed to the design of special material nozzles that can accurately and stably eject various tin wave heights, thereby enhancing the ability to weld repeatedly in limited spaces or near the parts. The welding pump, propeller, lifter, robot technology, nitrogen transportation, and temperature control technology, combined with our unique crest nozzle, enhance the system’s tin welding performance, resulting in high precision and fewer defective products.

The temperature control capability at the usage site is excellent. The nitrogen temperature control performance is good due to using the PID temperature control principle (0-400°C). Nitrogen is used for welding wave crest inerting and protection. This unique nitrogen direct heat system heats the wave’s crest, allowing the operator to choose whether to increase or decrease the temperature.

The system utilizes advanced robotic control technology with closed-loop servomotors, resulting in high accuracy, repeatability, and welding quality. The servomotors are intelligent and maintain perfect repeatability, while the ball screw and linear guide ensure accurate positioning, low noise, and smooth movement.

Additionally, the system is designed to reduce the use of consumable materials, resulting in lower costs. Only one tablespoon of tin is produced per shift, significantly reducing solder losses. The system does not waste nitrogen on motor cooling or pneumatic systems, as our nitrogen use efficiency is very high, at only 30 CFH. This is 15% to 65% lower than the nitrogen consumption of similar products.

The system requires minimal maintenance time, taking only 5-10 minutes to start maintenance, which includes cleaning work, removal of welding slag, hot soldering, etc. The pump needs to be cleaned for only 20-35 minutes after 80 hours of use, which is 50% less cleaning time than some competitors’ products. We implemented several innovative solutions to meet the design requirement of minimizing maintenance time. The propeller was designed to reduce pump speed, reducing the production of welding slag and the need for pump maintenance. Additionally, we added a heating plate outside the soldering furnace to increase heat capacity, prolong the heating part’s service life, improve the soldering furnace’s quality stability, and simplify cleaning. The solder pump utilizes heat insulation material and a heat-resistant conveyor belt to minimize heat transfer to the motor, extending its service life.

The system is easy to program and control with powerful industrial computer software, an elegant user interface, and fast programming speed. Programmers can easily convert imported scanned images or Gerber into a selective soldering system. The system’s direction, speed, pauses, and other attributes are controllable. The touch screen saves motion speed, temperature parameters, product count, peak height correction, and other transport guide parameters.

The selective spray part has an air outlet above the spray area to reduce flux pollution to the machine. The nozzle uses an imported atomizer nozzle and can also be equipped with an imported linear injection nozzle as needed. The flux is stored under pressure for irrigation, ensuring constant spray pressure and unaffected by the amount of flux.

The preheating part of the process involves using an infrared preheating device to preheat the products on the PCB board. This device has a small heating power and heat loss. The preheat temperature and preheat time can be set on the touch screen.

The selective tin furnace part includes a set of independent tin pump devices with peak height and correction that can be set independently. The external type of double heating plate allows for more perfect heat transfer. All furnaces use quick connector connections, eliminating the need for rewiring during replacement. Closed-loop servo-control regulates all wave peaks, which can be set to self-correct peak height at regular intervals. The welding process is displayed in real time through a camera and display. Additionally, the tin furnace is equipped with a tin-level alarm.

The conveyor mechanism utilizes a chain or roller transport system, with each guide being driven by an independent motor. The transport speed can be adjusted to meet specific needs. The guide rail transportation ensures smooth operation and long-term use without wear.

An optional wind speed cooling system is available, featuring an independent outlet cooling device for the machine. The cooling system is automatically activated after welding and switches off when the product transportation leaves the machine.

The solder filling system is designed to automatically refill the machine’s tin level when it falls below the alarm value. The automatic tin feeding system will shut down once the tin level reaches a certain level. The machine will then return to the designated working place and await further instructions.

The machine has a maintenance reminder function that prompts the user to perform maintenance work after a certain amount of continuous use. This helps to avoid any necessary maintenance being overlooked, which could negatively impact the machine’s function and lifespan.

Additionally, the machine can store parameters and temperature data in real time in a file format, although this feature is optional.