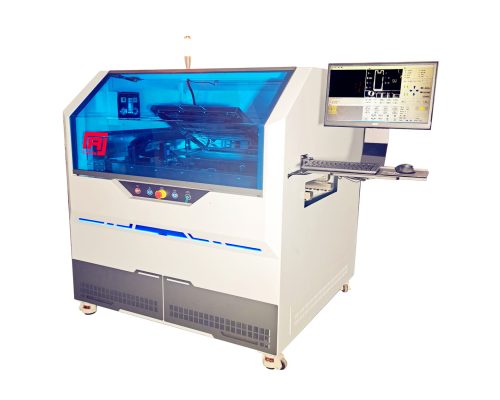

Large All-in-One Four-Head Selection Soldering Machine for Sale

Large All-in-One Four-Head Selection Soldering Machine

| project | TRJ-643D Plus parameter |

| Device name | Line four cylinder selection welding |

| Equipment model | TRJ-643D Plus |

| Overall dimensions | (L)3500*(W)1700*(H)1900mm |

| The net weight | 1800KG |

| The power supply | 3P 380V 50HZ (optional) |

| Normal machine power/total power | 9.5KW/15KW |

Product description

Main performance technical parameters

| project | TRJ-643D Plus parameter |

| Device name | Line four cylinder selection welding |

| Equipment model | TRJ-643D Plus |

| Overall dimensions | (L)3500*(W)1700*(H)1900mm |

| The net weight | 1800KG |

| The power supply | 3P 380V 50HZ (optional) |

| Normal machine power/total power | 9.5KW/15KW |

| The minimum PCB size | ≥L100mm ≥W50mm |

| Maximum PCB size | ≤L600mm ≤W600mm |

| Transport direction | Left to right |

| Transport guide | Fix the front and move the back |

| Transport height | 900+/-20mm |

| PCB The thickness of the | 0.5~6.5mm |

| PCB The upper part of the space | ≤100mm |

| PCB The lower space | ≤40mm |

| Edge clearance | ≥3mm |

| Spray system | |

| Spray way | Spray flux |

Description of equipment characteristics

The products have various applications, including solar energy, military equipment, aerospace, nuclear industry, automobile manufacturing, and electronics. They can be easily integrated into factory automation production lines and support multiple extensions.

The system utilizes closed-loop servomotors highly accurate and advanced robotic control technology. The ball screw and linear guide provide precise positioning, low noise, and smooth movement.

The nozzle is designed with unique material to accurately and stably eject various tin wave heights, improving the ability for continuously repeated welding in limited space or when too close to other parts. This allows for welding only where needed, without damaging other components.

The nitrogen direct heating system is used to inert and protect the soldering crest of the tin furnace while reducing the amount of tin slag produced. This system heats the wave’s crest using nitrogen and allows the operator to adjust the temperature.

The process parameters can be edited for greater flexibility, including the path starting point, welding time, moving speed, air travel speed, Z-axis height, and pump offset parameters.

Linear injection can be programmed to control flux consumption, resulting in less consumable material and lower costs for each solder joint.

Third, the choice of welding principle

The TRJ-642D Plus

The welding process involves feeding the plate, spraying flux and solder, preheating, welding, and then applying the plate.

The system is divided into three areas: a two-head spray and solder area, a single preheating area, and an independent double-head solder area. Each area works simultaneously to complete the flux spraying, soldering, preheating, and soldering functions.

Motion control system

The system’s platform allows for easy control of running, stopping, and speed, among other attributes. The touch screen can save motion speed, temperature parameters, product count, height correction of a wave crest, and automatic width adjustment of the guide rail.

Both systems use advanced robotic control technology, specifically the closed-loop server, an intelligent motor that maintains perfect repeatability and knows its position.

The system also features a ball screw and linear guide for accurate positioning, low noise, and smooth movement.

Five, Cam Conductor Programming software

The industrial computer system offline programming software has an elegant user interface and breakneck programming speed, making it easy to program the system. Programmers can convert images using imported scanned images or Gerber, select solder joints, configure nozzles, and form a selective soldering system in just a few minutes.

The parameters that can be edited include the starting point, welding time, moving speed, air travel speed, Z-axis height, and pump migration.