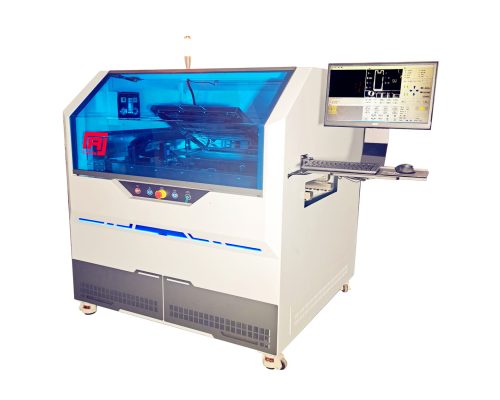

Selective Wave Soldering Machine for Sale

Selective Wave Soldering Machine

Machine model: TRJ-401 PLUS

Power supply: 1P 220V 50HZ (other voltages optional)

Normal machine power/total power: 2.8KW/5.8KW

Machine weight: ≥800KG

Overall dimensions: (L)1200*(W)1300*(H)1650mm

Minimum PCB size: L80mm W50mm

Maximum PCB size: L350mm W450mm

PCB thickness: 0.5~6mm

PCB weight: ≥5KG

Product description

Selective Wave Soldering Machine Technical Parameters

| The parameter name | TRJ-401Plus |

| Device name | Integrated single cylinder selective welding |

| The machine model | TRJ-401Plus |

| Overall dimensions | (L)1400*(W)1350*(H)1500mm |

| The net weight | 700KG |

| The power supply | 1P220V 50HZ |

| Transport height | 900+/-20mm |

| Into the direction of plate | Left to right |

| Transport guide | Fixed before,After moving |

| Normal machine power/The total power | 3.5KW/6.5KW |

| The minimumPCBsize | ≥L100mm ≥W50mm |

| The biggestPCBsize | ≤L400mm ≤W400mm |

| PCBThe thickness of the | 0.5~6.5mm |

| PCBThe weight of the | Max.9Kg |

| PCBThe upper part of the space | ≤130mm |

| PCBThe lower space | ≤40mm |

| PCBProcess side | ≥3mm |

The Working Principle

TRJ-401 Plus soldering process:

Feed plate → select position spray flux → select position weld → out the plate

The whole system is a closed-loop processing system.

Closed loop processing control

Feed plate → spray → preheat → welding → out plate

Description of soldering characteristics

Teljia Select Soldering has many applications and can be used conveniently in factory automation production lines. It also has several extended functions and can be used to weld a variety of mixed PCB boards either over the fixture or directly.

This material is suitable for a wide range of applications, including the design of high-performance nozzles for welding systems. It accurately and stably ejects various tin wave heights, improving the ability to continuously repeat welding in limited space or too close to parts. The welding system utilizes a welding pump, propeller, lifter, robot technology, nitrogen transportation, temperature control technology, and a unique crest nozzle to achieve high precision and minimize defective products.

The system also boasts excellent temperature control capabilities on-site, thanks to using nitrogen for welding wave crest inerting and protection. The PID temperature control principle is employed, with a 0-400 degrees range. This nitrogen-direct heat system heats the wave’s crest, and the operator can increase or decrease the temperature.

The system uses closed-loop servomotor technology for high accuracy, repeatability, and welding quality. The servo motor is an intelligent motor that maintains perfect repeatability and is guided by a ball screw and linear guide for accurate positioning, low noise, and smooth movement.

Motion control system

The system’s platform allows for easy control of running, stopping, and speed, among other attributes. The touch screen can save motion speed, temperature parameters, product count, height correction of a wave crest, and automatic width adjustment of the guide rail.

Both systems use advanced robotic control technology, specifically the closed-loop server, an intelligent motor that maintains perfect repeatability and knows its position.

The system also features a ball screw and linear guide for accurate positioning, low noise, and smooth movement.

Cam conductor Programming software

The industrial computer system offline programming software has a user-friendly interface and allows for fast programming. Programmers can convert imported scanned images or Gerber files, select solder joints, configure nozzles, and set up a selective soldering system in just a few minutes.

Additionally, the system allows for editing parameters such as starting point, welding time, moving speed, air travel speed, Z-axis height, and pump migration.

CCDVisual positioning system

The visual recognition system automatically adjusts based on the board’s offset.

The pewter height detection system

Accuracy test of tin spraying height:

To perform this test, a titanium alloy test plate is connected to a positive voltage and positioned on the side of the orbit. The plate’s coordinates relative to the origin are set in the system settings beforehand. After a certain number of products have been sprayed (adjustable), the plate will automatically move to the position of the test probe. Meanwhile, the system will gradually increase the motor speed applied to the wave peak. This will cause the spout tin wave to contact the test probe and connect the positive voltage. The system will then automatically modify and control the offset based on the measured results to achieve a stable wave.

Spray solder monitoring system

During soldering, the monitor displays real-time footage of the spray and welding situation to aid understanding.

Teljia’s specialized video software supports photo-taking and recording functions.

Frequently Asked Questions (FAQs)

Selective Wave Soldering Machine Price/Cost

The price of a selective wave soldering machine can vary widely depending on the features, brand, and capabilities. Contacting us directly or requesting a quote based on your specific requirements is recommended for the most accurate pricing.

Selective Wave Soldering Machine China

As China’s premier manufacturer of selective wave soldering machines, we take pride in being at the forefront of the industry, providing state-of-the-art solutions tailored to sophisticated electronic assembly processes. Our reputation for excellence stems from our relentless pursuit of innovation, quality, and customer service. With a rich heritage of engineering expertise and a keen understanding of the dynamic market, we deliver machinery that stands out for its reliability, precision, and advanced capabilities.

What is the warranty of your selective wave soldering machine?

Our company’s warranty for our selective wave soldering machines typically covers one year from the date of purchase. This warranty includes parts and labor for any manufacturing defects or malfunctions that may occur under normal operating conditions. During the warranty period, if any issues arise, we will provide repair services or replacement parts at no additional cost to ensure your machine remains operational and efficient.