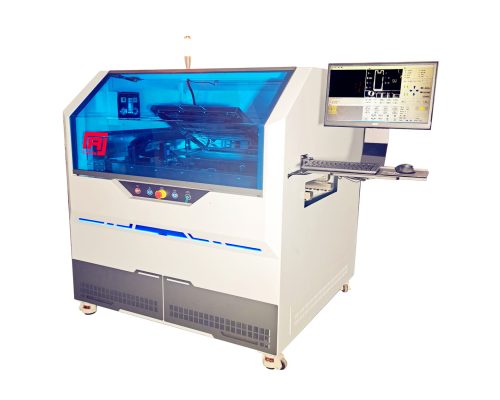

Offline Selection Of Soldering Machine for Sale

Offline Selection Of Soldering Machine

| The machine model | TSF-350 |

| The power supply | 1P 220V 50HZ (Other voltages are optional) |

| Normal machine power/total power | 1.8KW/4.0KW |

| Machine weight | ≥400KG |

| Overall dimensions | (L)1000*(W)950*(H)1200mm |

Product description

Main technical performance parameters

| project | Device description | The specific requirements |

| Model and power supply | The machine model | TSF-350 |

| The power supply | 1P 220V 50HZ (Other voltages are optional) | |

| Normal machine power/total power | 1.8KW/4.0KW | |

| Machine weight | ≥400KG | |

| Overall dimensions | (L)1000*(W)950*(H)1200mm | |

| PCBplate | Minimum PCB size | L50mm W50mm |

| Maximum PCB size | L350mm W350mm | |

| PCB The thickness of the | 0.5~6mm | |

| PCB The weight of the | ≤5KG | |

| PCB Height of upper element | ≤100mm | |

| PCB Bottom element height | ≤40mm | |

| PCB Process side | ≥3mm | |

| PCB Pin Foot spacing | ≥0.8mm | |

| Distance between solder pad and component | ≥1mm | |

| PCBfixed | PCB Place the height | 900 ±20mm |

| PCB Place for | Artificial and | |

| PCB Positioning way | The framework of mechanical | |

| PCB The Angle | The level of | |

| Spray welding module | Movement form | PCB doing XYZ sports |

| Flux capacity | ≥1.5L | |

| Flux type | Wash free/water based (solid content < 10%) | |

| Nozzle nozzle size | ≤130um | |

| Spray working pressure | 0.5~1bar(0.05Mpa~0.1MPa) | |

| FLUXNozzle origin | Germany | |

| Continuous spray spray speed | 0~20mm/s | |

| Moving positioning speed | 0~400mm/s | |

| Tin mouth specification | Standard welding head | |

| Tin furnace capacity | ≤8KG | |

| Minimum tin nozzle diameter size | ≥2.5mm | |

| Standard tin nozzle specification type support | ¢3-¢10 | |

| Tin stove temperature | At room temperature~350℃ | |

| The temperature control mode | PID | |

| Tin wave height | ≤5mm | |

| The tin time | ≤40min/(300℃) | |

| The welding precision | ±0.25mm | |

| Type of tin furnace pump | Mechanical pump | |

| N2 purity | O2 < 20 PPM,(99.999 %) | |

| N2 supply | 0.5Mpa 25L/min | |

| Oxidation capacity of spot solder furnace | At 1.5 m3 / h of nitrogen, the oxidation capacity is 0.2Kg/8h/ tin furnace | |

| software | The operating system | Windows |

| Software language | Available in simplified Chinese/traditional Chinese/English | |

| programmatically | Online/offline programming | |

| Data import | Supports Gerber conversion for image or scan image programming | |

| other | Automatic tinning device | ○ |

| Crest height detection | ○ | |

| Process visualization | ● | |

| N2 pressure warning system | ● | |

| Air pressure alarm | ● | |

| CCD Visual Mark point recognition | ○ | |

| CCD Visual displacement compensation function | ○ | |

| Spray test | ○ | |

| PCB surface temperature detection in preheating zone | ○ | |

| Function of preheating and reheating in welding area | ○ | |

| Function of preheating and reheating under welding zone | ○ |

instructions:●Indicates that this function item has, ○This feature can be added optionally, ※This is zero

Select welding features

1. Our company’s design and manufacture of selective wave soldering conform to relevant national standards. Reasonable structure layout, high mechanical, electrical, and control system reliability, and stable control accuracy can be maintained after long-term use.

2. Suitable for welding multi-variety, small-batch, and multi-batch products, flexible and convenient switching.

3. Convenient operation and maintenance of equipment.

4. The machine can be programmed offline or online and operate efficiently.

5. The original German FLUX spray nozzle is stable and durable.

6. The welding effect of the equipment can reach the IPC610D standard, which is widely used in aerospace, the military industry, automotive electronics, gas and instrumentation, and other vital fields.

Cam conductor Programming software

The industrial computer system’s offline programming software has an elegant user interface and breakneck programming speed, making it easy to program. Programmers can convert images using imported scanned images or Gerber, select solder joints, configure nozzles, and form a selective soldering system in just a few minutes.

Additionally, they can edit the starting point, welding time, moving speed, air travel speed, Z-axis height, and pump migration parameters.