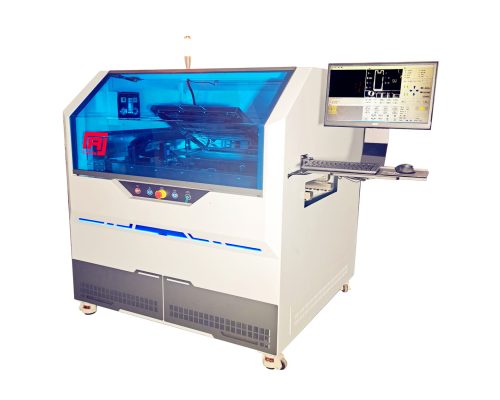

Offline Double-Head Selective Wave Soldering Machine for Sale

Offline Double-Head Selective Wave Soldering Machine

| The machine model | TSF-601DC Plus |

| The power supply | 1P 220V 50HZ (Other voltages are optional) |

| Normal machine power/total power | 4.8KW/7.5KW |

| Machine weight | ≥900KG |

| Overall dimensions | (L)1620*(W)1350*(H)1500mm |

Product description

Technical parameters of selective wave soldering

| project | Device description | The specific requirements |

| Model and power supply | The machine model | TSF-601DC Plus |

| The power supply | 1P 220V 50HZ (Other voltages are optional) | |

| Normal machine power/total power | 4.8KW/7.5KW | |

| Machine weight | ≥900KG | |

| Overall dimensions | (L)1620*(W)1350*(H)1500mm | |

| PCB板 | Minimum PCB size | L50mm W50mm |

| Maximum PCB size | L600mm W600mm | |

| PCB The thickness of the | 0.5~6mm | |

| PCB The weight of the | ≤5KG | |

| PCB Height of upper element | ≤100mm | |

| PCB Bottom element height | ≤40mm | |

| PCB Process side | ≥3mm | |

| PCB Pin Foot spacing | ≥0.8mm | |

| Distance between solder pad and component | ≥1mm | |

| Spray welding module | Flux capacity | ≥1.5L |

| Flux type | Wash free/water based (solid content < 10%) | |

| Spray working pressure | 0.5~1bar(0.05Mpa~0.1MPa) | |

| FLUXNozzle origin | Germany | |

| Continuous spray spray speed | 0~20mm/s | |

| Moving positioning speed | 0~400mm/s | |

| Tin mouth specification | Standard welding head | |

| Tin furnace capacity | ≤8KG | |

| Tin stove temperature | At room temperature~350℃ | |

| The temperature control mode | PID | |

| Tin wave height | ≤5mm | |

| The welding precision | ±0.25mm | |

| N2The purity | O2 < 20 PPM,(99.999 %) | |

| N2 supply | 0.5Mpa 25L/min | |

| Oxidation capacity of spot solder furnace | At 1.5 m3 / h of nitrogen, the oxidation capacity is 0.2Kg/8h/ tin furnace | |

| software | The operating system | Windows |

| Software language | Available in simplified Chinese/traditional Chinese/English | |

| programmatically | Online/offline programming | |

| Data import | Supports Gerber conversion for image or scan image programming | |

| other | Automatic tinning device | ○ |

| Crest height detection | ○ | |

| Process visualization | ● | |

| N2 pressure warning system | ● | |

| Air pressure alarm | ● | |

| CCD Visual Mark point recognition | ○ | |

| CCD Visual displacement compensation function | ○ | |

| Spray test | ○ | |

| PCB surface temperature detection in preheating zone | ○ | |

| Function of preheating and reheating in welding area | ○ | |

| Function of preheating and reheating under welding zone | ○ |

instructions:●Indicates that this function item has, ○This feature can be added optionally, ※This is zero